Your Cart is Empty

The reels are one of the 16 major components that make up a tape deck, and one of the most important when it comes to controlling sound quality. Reel players typically have two reels, a supply reel that holds the unplayed portion of the tape, and a takeup reel which receives the tape. Both reels are held by the capstan spindle which rotates to move tape through the tape head. Learn more about the 16 components that make up a reel player in our Ultimate Guide To Reel to Reel Tape Players. Our previous guide provides an overview of all the components, but today we're diving deep into reels.

Contrary to what may be first thought, the reels that hold the audio tape on an open reel tape deck can affect the performance of the tape deck and have a noticeable effect on sound quality. A poorly designed reel can upset the balance of tension on the tape as it traverses the tape heads, capstan and guides, and can cause damage to the tape itself and produce uneven layers on the spool as the tape is wound. A poor design can also result in damage to the edges of the tape when the flanges rub against the tape during motion.

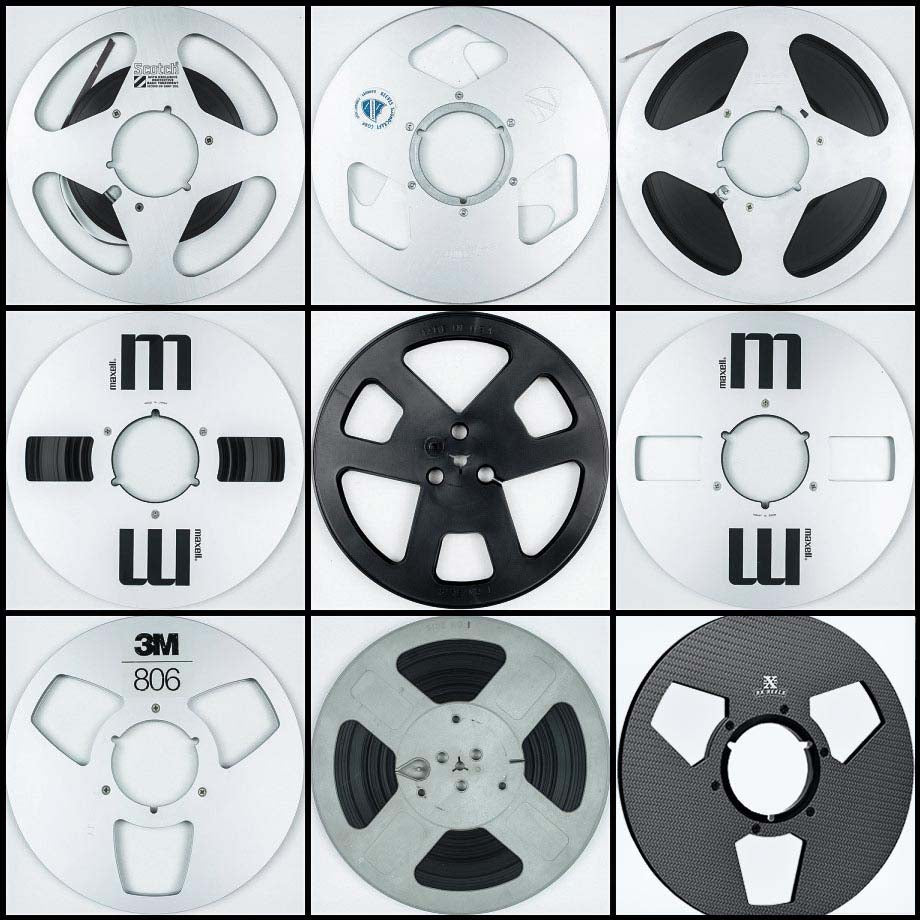

Before looking more closely at the role that the reels play in the performance of a tape deck, let’s first look at the different types of reels available.

For the domestic market, several sizes of reels have been produced over the years to suit the requirements of the destination machine:

Larger reels that have a 10½-inch or even a 12½-inch diameter are aimed at the professional tape market, which records music at the higher tape speeds of 15 IPS or 30 IPS for mastering. These reels usually have the larger diameter NAB centre (National Association of Broadcasters) to provide the more secure and stable connection to the spool that is required for professional use. Having said that, some 10½-inch reels are made entirely from plastic and are fitted with cine centres as a way of keeping down the cost of professional audio tape.

Most of the domestic cine reels, and certainly all of them below 7 inches, are made entirely from plastic and have hollow centre hubs. One of the problems with plastic is that it can distort easily when under pressure, which results in stress on the centre hub. Although not an issue for smaller reels where the stresses are lower, stress at the centre of the reel can cause significant problems for larger reels where a small misalignment at the centre can result in the flanges interfering with the tape path and rubbing against the edges of the tape while it is playing. Stress can also upset the balance of the reel, which can cause the spool to present a variable load to the spool motor or brake of the tape machine. It can even produce a slight wobble in the spool while playing. All this can exacerbate wow and flutter, which is certainly not good!

The term ‘wow’ describes low frequency variations of the tape speed and is often caused by reels that are out of balance or have flanges that rub on the edges of the tape or on the body of the machine, resulting in variable tape tension. Flutter is higher frequency fluctuations of the tape speed and can be caused by flanges that rub the tape, as well as problems in the tape path. Of course, both wow and flutter can also be a result of problems with the mechanics of the machine itself.

However, how does the stress in the centre of a reel arise? In order for tape to be wound onto a reel, the tape has to be put under a slight tension to ensure that the layers are smooth and the tape does not run the risk of wrinkling. Even with the gentle tension provided by the take-up spool motor, the resulting stress on the centre hub will gradually build up with the consecutive layers of tape on the reel, and by the time the tape is fully wound onto the reel, the stresses at the centre of the reel can be quite large. This can result in distortions of the reel, and in extreme cases, even fractures of the plastic around the centre, which I have seen on several occasions.

For the above reasons, many of the 7-inch reels used for domestic hi-fi have aluminum flanges that are secured to a solid plastic centre hub with three fixing screws. Virtually all of the professional 10½-inch reels have metal flanges that are secured to a solid plastic centre hub with three or more screws. It is the cheaper professional reels that usually have only three screws and, therefore, a less secure coupling to the centre hub. Better quality reels have five screws and the best reels have six screws.

Of course, metal flanges can also present issues. It is possible for the metal to become slightly bent with constant handling, especially in a studio environment or when used constantly as a take-up reel. This can result in the flanges scraping the edges of the tape and also scuffing the back plate of the tape machine. Additionally, the reel can become out of balance, resulting in spool wobble and leading to an increase in wow and flutter.

The other issue with metal flanges is that they are relatively heavy, compared to plastic. This extra weight increases the inertial load on the spool motors, making them less able to respond quickly to changes in the speed of winding. This is particularly relevant to professional machines, which often have variable speed winding to assist in cuing. An ideal flange would be very lightweight, yet rigid. Carbon fibre is therefore an excellent choice of material for a flange.

Lastly, let’s look at the composition of the centre hub itself. The hub needs to be rigid and robust in order to withstand the forces exerted on it, and perfectly balanced. Although more expensive to manufacture than a plastic hub, an aluminum centre hub that is precision-made will have the necessary strength to withstand all the forces that it is likely to encounter in use. It must also be machined to tight tolerances to ensure a perfectly balanced reel. A spool that is even slightly out of balance can affect the tension on the tape as it is playing, and this can result in tiny amounts of wow and flutter, especially at the faster professional speeds of 15 or 30IPS. This wow and ‘micro-flutter’ can have an adverse effect on the sound. A perfectly balanced spool, such as the RX Reels spool, ensures a consistent tension during playing and also reduces wear and tear of the tape deck mechanism.

With all the above in mind, it can be appreciated that the RX Reel with its carbon fibre flanges, milled solid aluminum centre hub and twelve fixing screws (six per side), addresses all of the above issues and comes very close to being the perfect reel for high-end audio systems. This reel poses little risk of damaging the magnetic tape and will reduce unnecessary wear on the spool motors and bearings, as well as minimising wow and flutter during operation.

When I use the RX Reel on my Studer A810 tape deck, rather than a standard spool fitted with aluminum flanges and a plastic hub, I definitely have a sense of a slightly wider sound stage and clearer instrument imaging. These improvements add to the overall sense of realism. Having attended a number of live recording sessions in recent years, I can honestly say that the use of high quality reels does bring a recording a step closer to the real thing!

We hope you found this post helpful for understanding more about Reels for Open Reel Tape Decks. For a list of Where to Find Quality Pre-Recorded Music on R2R Tape check out our blog post here.

RX Reels prides ourselves on manufacturing the world's best carbon fiber reels. Learn more about us and why Hi-Fi World's Martin Pipe has said "Quite frankly, it's highly unlikely you'll find a better spool for your deck" and rated RX Reels "5 Worlds - amongst the best."

A Chartered Scientist, Chartered Engineer, Chartered Physicist and a Fellow of the British Institution of Engineering and Technology, Neville has worked as a Director of the British National Health Service, as well as for the Ministry of Defence and in private industry. He’s a lifelong audio enthusiast and regular contributor to British hi-fi magazines, as well as StereoNET International. He has a passion for valves, vinyl and professional open reel tape.

See RX Reels Carbon Fiber 10.5" and 7" reels here.

Looking for a great player? See Our Ultimate Guide to Reel to Reel Players

This post delves into the topic of making enhancements to the actual recorded media on reel-to-reel tape. Numerous vinyl albums have been remastered, and indeed, several hundred tapes have undergone remastering from the master or near-master. These offer notable improvements in sound quality compared to the original recordings. Sonorus Audio offers a Holographic Imaging tape remastering service explored here.

Analog Audio Design's first product, the TP-1000 is wholly constructed from new components, utilizing technologies such as computer-aided design and advanced testing tools to augment tape transport and minimize distortion.

The all important heads are from AM Belgium, the same company that inherited the head technical specs directly from Studer / ReVox when they shut down.

The TP-1000 stands out as a three-motor machine using DC motors, all uniquely coupled by a belt and a flywheel to a modern design. Why? To reducing the cogging and flutter commonly associated with DC motors.